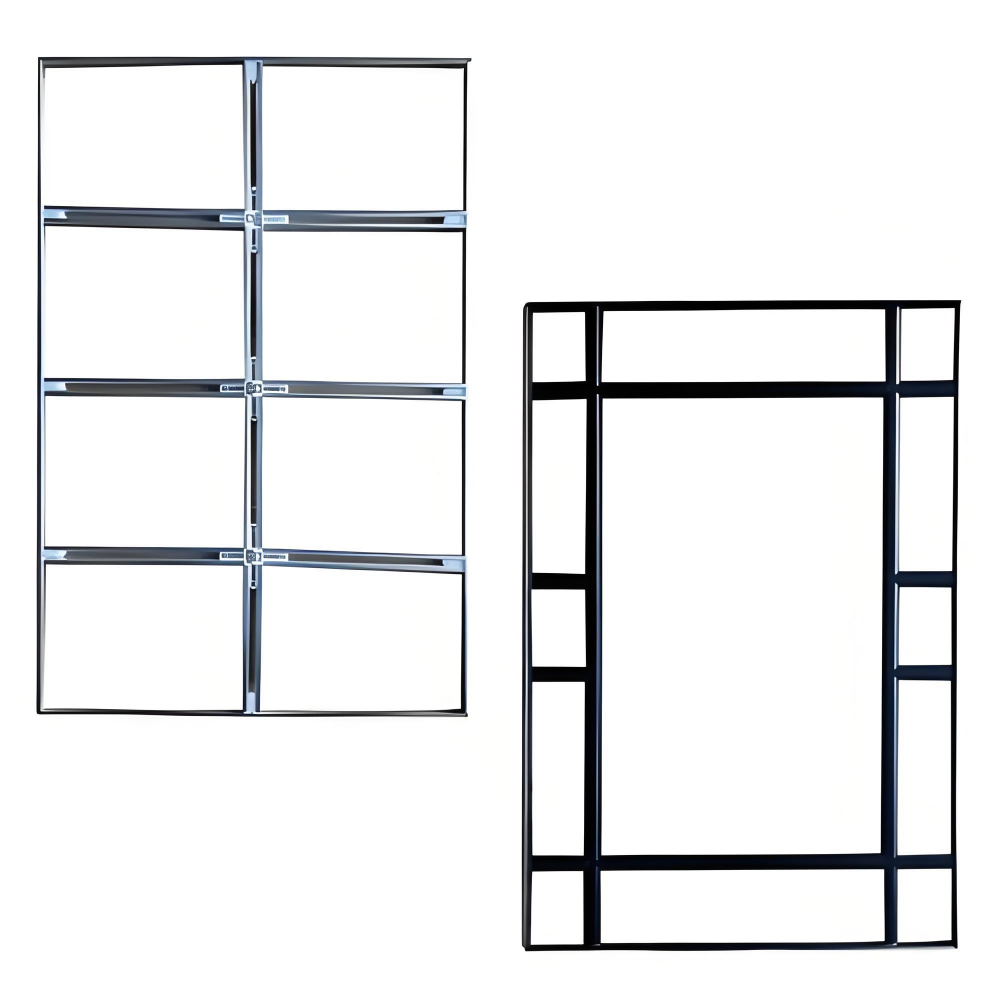

The built-in beauty strip glass is composed of two or more pieces of glass, with beauty strips containing beauty patterns or textures embedded in the glass interlayer. Its advantage lies in integrating decorative elements into the glass itself, which can present rich and diverse visual effects such as landscapes, flowers, geometric patterns, etc., adding an artistic atmosphere to indoor spaces. Glass has strong integrity and is easy to clean and maintain. Simply wipe the surface of the glass, and the decorative effect is long-lasting. It is suitable for partitions, screens, background walls, and other locations in homes, hotels, shopping malls, and other places, enhancing the beauty and grade of the space.

Possessing the capability to develop aluminum alloys, we can tailor alloy combinations according to customers' varying performance requirements. This not only fulfills their needs for product performance and lightweight design, but also achieves cost savings.

Based on the product's accuracy and performance requirements, we can independently design the production process route, which greatly enhances the performance of the welded parts and ensures the dimensional accuracy of the assembly.

Possess the ability to develop and modify extrusion and stamping molds, thereby reducing mold development costs.

Possessing automated extrusion production lines and CNC production lines has reduced labor cost.

With advanced production lines for surface treatment including oxidation, electrophoresis, and painting, we can not only meet different customer requirements but also reduce equipment investment costs.

The group currently boasts over 150 extrusion production lines ranging from 600 to 10,000 tons, with an annual production capacity of 800,000 tons, of which 40% are above 2,000 tons. These lines include various specifications of extruders ranging from 500 to 10,000 tons. The sixth factory is primarily dedicated to the production of industrial profiles and lightweight automotive profiles, with ample production capacity to meet customers' extrusion needs for various sizes and specifications.

It has established a national-level standard testing center, which has obtained the China National Accreditation Service for Conformity Assessment (CNAS) laboratory accreditation and the China Metrology Accreditation Scheme (CMA) for inspection and testing institutions. It has also jointly established 13 high-standard laboratories, including chemical analysis room, metallographic laboratory, mechanical property laboratory, physical property laboratory, spectral laboratory, salt spray laboratory, and aging laboratory. Key instruments and equipment have been imported from the United States, Germany, Israel, and other countries.

The group has over 20 years of experience in aluminum extrusion, and through years of verification and accumulation, has formed a rich database of data: product database, design standards, analysis specifications, DFMEA, PFMEA, control plans, process verification data, etc.